CT Products & Solutions

- ISO 13485 Platinum Certified Process

- Nationwide Service Coverage

- Extensive Mobile CT Rental Fleet

- Fixed and Mobile Sales Solutions

- Supplies and Accessories

- Robust Parts Inventory/Parts Repair

- Radiation Protection Room Shielding Services

- Installation

- De-Installation

- Consulting

- Relocation Services

- Applications Training

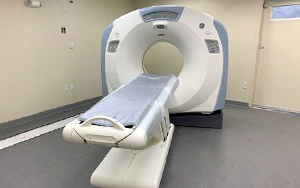

Nationwide Imaging Services (NIS) provides you with several choices across multiple brands of pre-owned and reconditioned equipment. Our quality CT systems come with an NIS warranty. We can also take your old system in on trade to offset the cost of your new scanner. Service Solutions are tailored to the clinical and economic needs of the facility to include Full Service, Shared Service, PM Agreements and other options.

Our customizable CT service solutions can include full-service contracts for most major platforms, time and materials service, preventative maintenance, equipment accreditation consulting, remote service support, as well as tube installation and calibration services. Mobile CT scanner lease and rental options are also available.

At NIS the quality starts with the selection of the equipment we purchase. Since we perform our own warranties and service, we must select only the finest in pre-owned devices so that we can minimize our exposure to after installation service problems.

Our Platinum Certified Process is available for most systems. This ISO certified process includes a multi-point inspection and these units carry a full 1-year warranty. This represents an exceptional offering that will allow you to increase image quality, speed of acquisition, patient safety, and ultimately, increase patient and user satisfaction. Our Platinum Certified products will maximize the revenue potential of your organization, while lowering your total cost of ownership.

As part of the MXR Imaging family, NIS offers a complete selection of computed tomography imaging systems supported by decades of industry expertise. Visit the MXR Imaging CT scanners page to explore all the CT brands and models Nationwide has to offer, with in-depth descriptions that highlight key features, benefits, and applications. Our team is here to help you choose the best solution and find the right equipment tailored to meet the specific needs of your facility.

Phone: (732) 262-3115

Email: info@nationwideimaging.com

Contact Us To Find Out More